This blog is NOT instruction.

Before beginning any reloading, take a class! This material only highlights areas that may be of interest for those considering reloading rifle ammo and all sections require training, further research and practice. This is NOT a step by step tutorial and do not use it as such. KJD Firearms Training offers reloading classes. Go to: http://www.nrainstructors.org/searchcourse.aspx to find the schedule and prices.

Headspace is critical

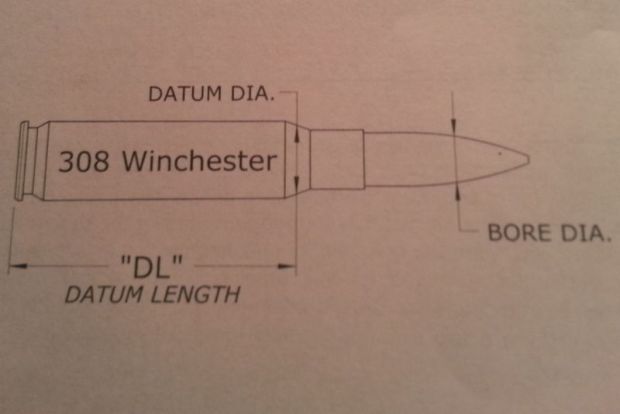

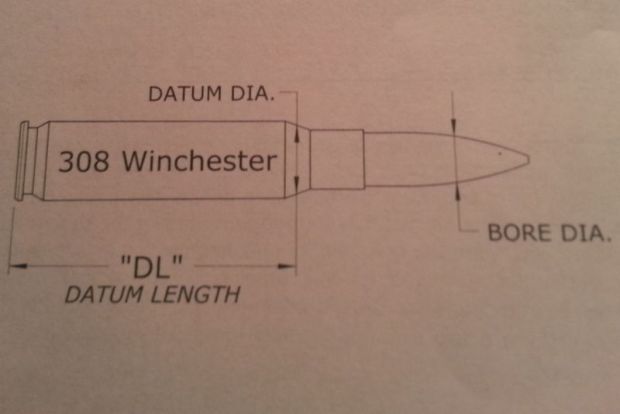

For rifle (bottleneck) shells, the term headspace refers to the distance from the breech face (bottom of shell) to the datum diameter of the shoulder . This is called the Datum Length (DL). Since the amount of shoulder bump is under the control of the re-loader, the “DL” dimension can be matched to any chamber by proper adjustment of the sizing die.

Datum Length (DL) specifications are published for every caliber by the Sporting Arms & Ammunition Manufacturer’s Institute (SAAMI) and there is a tolerance of .010” that is allowed. This means that the re-sized shells should be close to SAAMI’s specifications (within .010” of SAAMI’s specifications).

There are tools to help the re-loader adjust the resizing die so that the sized shells are close or at SAMMI specifications ensuring maximum case life and accuracy from reloads. Some of these tools include:

RCBS Precision Mic and Redding’s Instant Indicator.

These tools are sold caliber specific as they include a measuring component that allows the re-loader to get close to SAMMI specifications.

Redding’s Instant Indicator

This unit requires the use of a single stage, stand alone press. Consequently, if you have only one press then the Instant Indicator may be a bit of a challenge to use frequently and it should be used frequently.

There are multiple parts included as well as a set of directions. Although well written, a good video goes a long way to clarify how to use this tool. Two videos on “Ultimate Reloader” demonstrate two (out of four) functions of the Instant Indicator. Each of these videos are about 10 minutes in duration and well worth the time to watch.

Sizing: http://ultimatereloader.com/2011/10/16/ar-308-precision-loading-pt-1-case-sizing-and-trimming/

Bullet Seating: http://ultimatereloader.com/2011/10/27/ar-308-precision-loading-pt-4-seating-bullets-checking-concentricity/

Pictured below are the parts of a Redding Instant Indicator:

A – Dial Indicator; B – Die Body; C – Adapter & Pressure Spring; D – Set Up Gage; E – Should contactor; F – Bore Diameter Bushing; G – Blank Contractor

The Instant Indicator consists of a die body with a precision dial mounted on top. The Adapter & pressure spring sit on top of the die body and the Dial Indicator is inserted into the Adapter.

The other internal parts are:

Shoulder contractor is the part that contacts the cartridge case shoulder at the datum point. It is hallow with a black knurled cap threaded into the top.

Blank contractor has a solid blank finish with a precision ground surface at each end. Both ends are identical so insert with either end up.

Set up Gage is a hollow brass gage identified with the cartridge designation. The shoulder angle, datum diameter and datum length (DL) of the gage are made to SAMMI minimum chamber specifications.

Bore Diameter Bushing is a standard Redding neck sizing bushing (selected at bore diameter) that is used to establish the bore diameter contact point when using the indicator to compare bullet seating depth.

Pressure Spring is designed to fit the shoulder contractor cap and either end of the blank contractor. It is used to maintain a uniform contact pressure, insuring consistent readings.

Headspace

To assemble accurate reloads, it is important to understand “headspace” and how it’s related to the firearm’s chamber. Chamber headspace is determined in many different ways, depending on cartridge type (i.e. rimmed, rimless, rebated rim or belted). Most important to the reloader is the measurement from the base of the case to the datum diameter on the shoulder. This dimension is indicated in the following diagram as the Datum Length (DL) dimension:

The amount of shoulder bump is under the direct control of the reloader and so this DL dimension can be matched to any chamber by proper adjustment of the sizing die using the Instant Indicator. This helps ensure extended case life as well as improve accuracy of the reloads.

Using the Set up Gage

To calibrate the Instant Indicator to the minimum chamber specification, slide the Set Up Gage (D) into the shell holder and raise the ram in the press. Loosen the lock screw that retains the dial indicator and raise or lower the dial indicator slightly (it moves very easily) until the needle is near the 12 o’clock position. Tighten the lock screw on the Adapter then rotate the dial indicator face (push back slightly to move) until the zero is aligned with the needle. The Instant Indicator is now calibrated to reference the SAAMI minimum chamber headspace specification.

Start with brass fired from your rifle, 10 or 20 cases and measure each in the Instant Indicator. Do not take an average, the highest reading will most closely indicate the “DL” dimension of your rifle. For example, if the longest reading is .004”, this indicates that the chamber is .004” longer than the minimum and well within the .010” that SAAMI allows for most cartridges.

Sizing the cases

Install the sizing die in the press until it contacts the shell holder when the ram is raised to its uppermost position. Lower the ram and raise (unscrew) the die ¼ to 1/3 of a turn. Size several cases and compare their DL dimension to the previous readings you obtained. If the DL dimension of the cases decreased, raise the die an additional ¼ to 1/3 turn and start with several new fired cases. Most likely, the DL dimension either stayed the same or increased slightly. If so adjust the sizing die down a very slight amount and try again. Repeat this process until you observe .002-.003” of shoulder bump for cases to be fired in most firearms. In the previous example, the fired cases that were .004”, would read .001” or .002” after sizing. Cases to be fired in semiautomatic firearms should have their shoulder bumped .004-.006” and the indicator should read .098”, .099” or .000” of the cases started at .004”. When you have the die adjusted properly, tighten the lock ring to keep it set.

Note: It is good to start off with purchased new (or once fired) brass, e.g. Lapua. This will limit fluctuations in DL, something you will experience with brass picked up at a range.

In Part 4, other functions of the Redding Instant Indicator will be covered as well as measuring tools from Hornady.